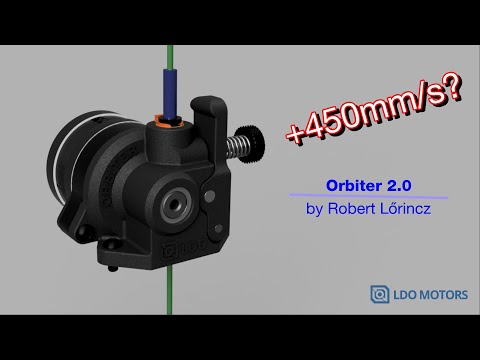

LDO Motors Orbiter Extruder V2.0

High-performance direct drive extruder in a compact design

€ 57,49

(All prices excl. VAT. - Excludes delivery costs)

Features & Advantages

- For 1.75 mm filaments

- With hardened dual gears

- Higher extrusion force

- Wear resistant, compact & lightweight

Item no.: LDO-OBT-V2, Content: 1 pc, EAN: 9010707003328

Product information & technical details

- Item no.: LDO-OBT-V2

- Manufacturer No.: OBT-V2

- Manufacturer: LDO Motors

- Content: 1 pc

- Product type: Extruder

- Filament Diameter: 1,75 mm

Description

Orbiter Extruder V2.0 is a direct drive extruder for 1.75 mm filaments that has been optimised in many ways compared to its predecessor, as well as being lighter, more compact and shorter. The extruder is made of qualitative components such as an injection-moulded housing (GPA12) resistant to high temperatures up to 200 °C and hardened gears from Bondtech, which help it to achieve more mechanical performance and a higher success rate.

The Orbiter V2.0 features Bondtech-quality hardened dual drive gears, shortened to 11mm, that grip filament from both sides. The gears have been reversed, which means the filament path is now closer to the extrusion center. Changes to the motor design contribute to the Orbiter V2.0's approximately 40% higher extrusion force and better acceleration performance compared to the previous V1.5 version.

The extruder is extremely wear-resistant, making it suitable for applications with abrasive materials.

Other features compared to the previous version:

► The weight has been reduced to about 135 grams

► The extremely powerful LDO-36STH20-1004AHG LDO stepper motor provides excellent performance with a retraction speed of 120 mm/s and acceleration of up to 8000 mm/s²

► The Dupont Delrin planetary gear makes very little noise and has low friction

► The PEEK gear sleeve has been revised and is now made of a hard and more mechanically resistant material

► A clamping mechanism with a clamping screw (captive grab screw) has been added for a better grip

► The perfectly aligned filament path results in a higher extrusion force

► Mounting screws are in line with the filament exit path, increasing the rigidity of the housing as well as making assembly easier

► The gap between the stainless steel filament exit guide and filament feeding mechanisms is about 0.2-0.3mm, ensuring the best TPU printing experience

► The design of the PTFE inlet coupling has been improved and reduced in size

► The position of the motor has been rotated by 10 degrees to facilitate its maintenance and installation

► An additional filament sensor has been equipped with an automatic charge and discharge button

Tip: With its revised and optimised design, the Orbiter V2.0 is the perfect fit for Delta printers.

Go here for firmware configurations and other useful links and information.

Spare parts

Product videos:

Questions & Answers about LDO Motors Orbiter Extruder V2.0

-

Are the extruder gears genuine bondtech gears?

-

What current does this use?

Customer Reviews

1 English review written for LDO Motors Orbiter Extruder V2.0

1 customer review in all languages

| 5 stars | | 3 | (100%) |

|---|---|---|---|

| 4 stars | | 0 | (0%) |

| 3 stars | | 0 | (0%) |

| 2 stars | | 0 | (0%) |

| 1 Stars | | 0 | (0%) |

3 reviews

1 customer review in English

1 customer review in all languages

Brilliant

Rated with 5 out of 5 stars.

Combined with a TMC2209 driver, this produces excellent results and works as well with low SH TPU as it does with carbon infused PETG. Very pleasing, especially for the price.

Was this rating helpful? (0) (0)